In SOLIDWORKS, Instant3D allows some of the same easy drag and drop techniques, but its reliance on an ordered feature environment becomes the limiting factor. Solid Edge has that ability, but it also has the ability to move into the Synchronous Technology environment in which we can drag and drop features, or make edits to solid bodies without relying on any underlying sketch. In Solid Edge’s ordered mode, features rely on defined 2D sketches to build their geometry the software reads them in order.

To understand the difference between Synchronous Technology of Solid Edge and Instant3D in SOLIDWORKS, I should point out that Synchronous Technology does not work in an ordered fashion. In comparing Synchronous Technology to Instant3D (SOLIDWORKS’ version of direct modeling), Synchronous Technology makes complex edits in a simpler manner, reduces the impact caused by varying design techniques or imported geometry modeling, and ultimately reduces the time it takes to create a useful design. When it comes to making changes on the fly, where many features must be directly edited at once, then Solid Edge has an advantage. After all, both require the same knowledge of fundamental design and engineering. If everything were to go according to plan in which the first design is always usable, then I would put Solid Edge and SOLIDWORKS neck and neck for their performance and capabilities.

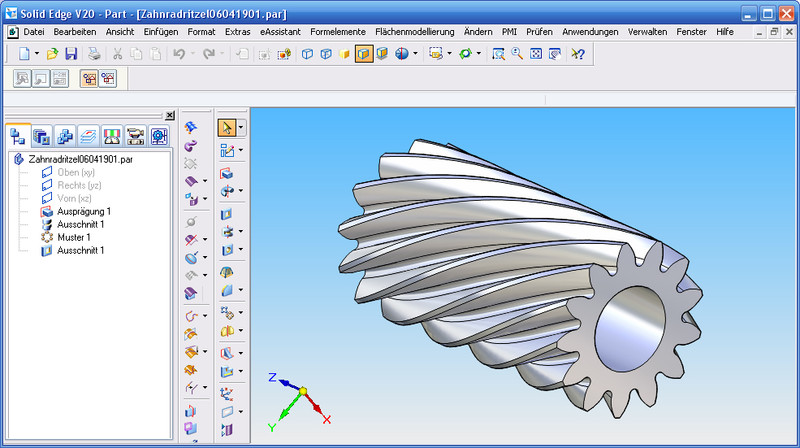

The core of both programs is a CAD system tailored to engineers who need to create part designs and manufacturing drawings for projects that move to fabrication or manufacture. By Chris McAndrew When it comes to comparing direct modeling in Solid Edge with SOLIDWORKS, there is one fundamental question: Is Synchronous Technology good enough to put Solid Edge over the top?

0 kommentar(er)

0 kommentar(er)